In the ever-evolving world of industrial machinery and processes, efficiency and precision are paramount. One of the unsung heroes in this realm is the rotary vane vacuum pump. These remarkable devices play a crucial role in various applications, from manufacturing and laboratory processes to automotive and medical industries. In this comprehensive article, we will delve into the world of rotary Vane Vacuum Pumps, unraveling their intricate mechanisms, applications, advantages, and why they are a vital component in achieving high-quality vacuum technology.

Understanding Rotary Vane Vacuum Pumps

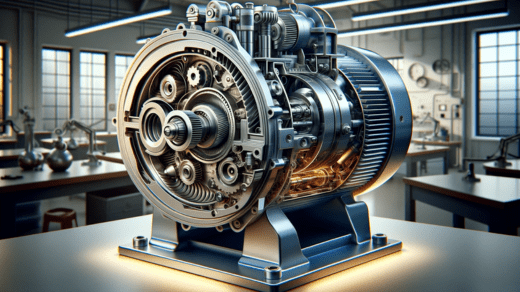

Rotary vane vacuum pumps, often referred to as oil-sealed rotary vane pumps, are a type of positive displacement pump used to create a vacuum within a closed system. They operate on a relatively simple yet highly effective principle that involves a rotating rotor with multiple vanes inserted inside a cylindrical chamber. The rotor is eccentrically mounted within the chamber, and as it spins, the vanes move in and out due to centrifugal force and contact with the chamber’s inner wall.

How Do Rotary Vane Vacuum Pumps Work?

The operation of rotary vane vacuum pumps can be summarized in a few key steps:

- Intake Phase: During this phase, the vanes are pushed outward by centrifugal force as the rotor rotates. As they move away from the chamber’s wall, an inlet valve opens, allowing atmospheric air to enter the chamber.

- Compression Phase: As the rotor continues to rotate, the vanes gradually slide back towards the chamber’s wall, compressing the incoming air. This compression reduces the volume of the air, leading to an increase in pressure.

- Exhaust Phase: Once the compressed air reaches a predetermined pressure level, an exhaust valve opens, allowing the compressed air to exit the pump. This creates a partial vacuum within the chamber.

- Repetition: The above phases are continuously repeated, creating a continuous flow of air from the inlet to the outlet while maintaining the vacuum within the chamber.

Applications of Rotary Vane Vacuum Pumps

Rotary vane vacuum pumps find extensive use across various industries due to their reliability, efficiency, and versatility. Here are some key applications where these pumps shine:

1. Manufacturing

In the manufacturing sector, rotary vane vacuum pumps are employed in vacuum molding processes, where they help shape various plastic and rubber products. They also assist in degassing, ensuring that no air bubbles are trapped in the final product.

2. Laboratory and Research

Laboratories and research facilities rely on rotary vane vacuum pumps for tasks such as vacuum filtration, solvent evaporation, and freeze-drying. These pumps provide a consistent and controlled vacuum environment, essential for accurate experiments and analyses.

3. Automotive Industry

Rotary vane vacuum pumps play a vital role in the automotive industry by aiding in power brake systems. These pumps ensure that the brake booster has a reliable vacuum source, contributing to safer and more efficient braking.

4. Medical Applications

Medical equipment, such as vacuum ovens and freeze dryers, depends on rotary vane vacuum pumps to maintain the necessary vacuum conditions for preserving pharmaceuticals, biological samples, and medical devices.

5. Electronics Manufacturing

In the electronics industry, these pumps are used for vacuum encapsulation and vacuum drying processes. They help eliminate moisture and air from sensitive electronic components, ensuring their longevity and functionality.

Advantages of Rotary Vane Vacuum Pumps

Now that we have a solid understanding of how rotary vane vacuum pumps operate and where they are commonly employed, let’s explore the advantages that make them indispensable:

1. Reliability

Rotary vane vacuum pumps are renowned for their robust and durable construction. They can withstand continuous operation for extended periods without compromising performance.

2. Low Maintenance

Minimal maintenance is required to keep these pumps in peak condition. Routine oil changes and basic checks are usually sufficient to ensure their longevity.

3. Efficient

These pumps offer high pumping speeds and excellent ultimate vacuum levels, making them efficient in creating and maintaining vacuums.

4. Quiet Operation

Compared to some other vacuum pump types, rotary vane vacuum pumps operate relatively quietly, reducing noise pollution in industrial settings.

5. Cost-Effective

Considering their longevity, low maintenance, and efficiency, rotary vacuum pump provide a cost-effective solution for a wide range of applications.

In this article, we’ve explored the world of rotary vane vacuum pumps, gaining insights into their inner workings, applications, and the advantages they bring to various industries. From manufacturing and laboratories to automotive and electronics, these pumps are the unsung heroes that contribute to the efficiency and precision of countless processes.

So, the next time you encounter a vacuum-sealed product, a laboratory experiment, or even a smoothly functioning brake system in your car, remember that the power behind these innovations often lies in the silent but indispensable rotary vane vacuum pump.