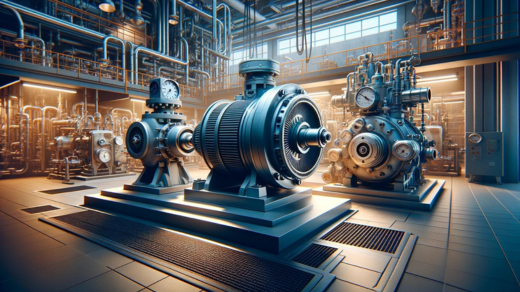

Vacuum pumps are integral to numerous industrial processes, facilitating the removal of air and creating vacuum conditions essential for various applications. Among the diverse types available, two stand out: the side channel vacuum pump and the Dry Vacuum Pump. Manufacturers like becker-international offer cutting-edge solutions in both categories.

Understanding Side Channel Vacuum Pump Technology

A side channel vacuum pump operates on the principle of centrifugal force, utilizing rotating impellers to create suction and generate a vacuum. Its unique design allows for continuous operation and efficient handling of both air and gases, making it ideal for diverse industrial tasks.

Applications of Side Channel Vacuum Pump

The versatility of the side channel vacuum pump makes it indispensable in applications such as vacuum packaging, pneumatic conveying, and printing processes. Its compact size and high efficiency make it a preferred choice across various industries, ensuring optimal performance and productivity.

Advantages of Side Channel Vacuum Pump

One of the key advantages of the side channel vacuum pump is its reliability and durability. With minimal moving parts and robust construction, it offers consistent performance even in demanding environments. Additionally, its energy-efficient operation helps reduce operational costs over time.

Exploring Dry Vacuum Pump Technology

In contrast, the Dry Vacuum Pump operates without the need for lubricating fluids, making it ideal for applications where cleanliness is paramount. becker-international offers a range of dry vacuum pumps designed to meet the stringent requirements of modern industrial processes.

Types of Dry Vacuum Pump

Dry vacuum pumps come in various configurations, including scroll, claw, and screw pumps, each offering unique benefits suited to specific applications. These pumps ensure contaminant-free environments, making them essential in industries such as semiconductor manufacturing and pharmaceutical production.

Advantages of Dry Vacuum Pump

The primary advantage of the Dry Vacuum Pump lies in its ability to maintain a clean and sterile environment, crucial for industries where even minor contamination can affect product quality. Additionally, its oil-free operation reduces maintenance needs and enhances operational efficiency.

Side Channel Vacuum Pump vs. Dry Vacuum Pump: A Comparison

When comparing the side channel vacuum pump and the Dry Vacuum Pump, several factors come into play. While both offer efficient vacuum solutions, their performance characteristics and maintenance requirements differ, making it essential to choose the right pump for specific applications.

Selecting the Right Vacuum Pump for Your Application

When selecting a vacuum pump, considerations such as operating conditions, desired vacuum level, and application requirements are crucial. becker-international provides expert guidance in choosing the most suitable vacuum pump solution tailored to meet specific industrial needs.

Benefits of Partnering with becker-international

As a leading manufacturer of vacuum pump technology, becker-international offers a comprehensive range of solutions designed to optimize performance and efficiency. With a focus on innovation and quality, becker-international is committed to delivering superior vacuum pump solutions to industries worldwide.

Environmental Impact of Vacuum Pump Technology

In today’s environmentally conscious world, the environmental impact of vacuum pump technology cannot be overlooked. Both the side channel vacuum pump and the Dry Vacuum Pump offer energy-efficient operation and reduced emissions, contributing to sustainable manufacturing practices.

Case Studies: Success Stories with Vacuum Pump Solutions

Real-world examples highlight the effectiveness of side channel vacuum pump and Dry Vacuum Pump solutions in various industrial applications. Case studies showcasing specific challenges, solutions, and outcomes provide valuable insights into the practical benefits of these technologies.

Tips for Maintaining Vacuum Pump Performance

Regular maintenance is essential for ensuring optimal performance and longevity of vacuum pumps. Simple practices such as monitoring operating parameters, lubricating moving parts, and scheduling preventive maintenance tasks can help maximize pump lifespan and minimize downtime.

Optimizing Industrial Processes with Vacuum Pump Solutions

In conclusion, the side channel vacuum pump and the Dry Vacuum Pump play vital roles in optimizing industrial processes across diverse industries. Whether it’s achieving high suction capabilities or maintaining a clean and sterile environment, these pumps offer efficient and reliable solutions for modern manufacturing challenges.